Views: 4 Author: Site Editor Publish Time: 2025-04-09 Origin: Site

When it comes to high-precision manufacturing, CNC machining is one of the most effective and efficient methods available. At Xuan Nan, we are dedicated to offering top-notch CNC machining services, enabling businesses to create metal and plastic components with complex geometries and tight tolerances. Whether you're in the automotive, aerospace, medical, or electronics industry, our expert team can handle projects of any complexity, ensuring high-quality results and fast turnaround times.

In this blog, we’ll introduce you to the world of CNC machining, explain how our services stand out, and describe the added value we bring to your projects. Discover why Xuan Nan is your trusted partner for CNC machining manufacturing.

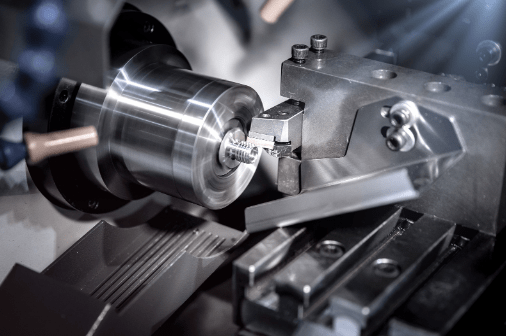

CNC machining (Computer Numerical Control machining) is a manufacturing process where pre-programmed computer software controls the movement of tools to produce parts. CNC machines use a variety of operations, including milling, turning, and grinding, to create highly precise components from raw materials like metal and plastic. The ability to handle complex geometries and tight tolerances makes CNC machining one of the most versatile manufacturing methods available.

At Xuan Nan, we provide a comprehensive range of CNC machining services designed to meet the needs of a wide variety of industries. Here’s a closer look at the key features that make our CNC machining services stand out:

We utilize advanced machinery, including 3-axis, 4-axis, and 5-axis CNC machines, as well as CNC lathes and EDM (Electrical Discharge Machining) equipment. Our machines are capable of handling complex parts and intricate geometries, ensuring that we can meet the demands of any project.

CNC Milling Machines: With over 25 sets of CNC milling machines, we offer both horizontal and vertical milling capabilities to suit different machining needs.

CNC Lathes: Our 10 sets of lathe machines allow us to efficiently produce cylindrical parts with tight tolerances.

EDM Machines: For intricate cuts and shapes, we offer EDM services to produce parts with high precision and minimal material wastage.

We understand the importance of accuracy in every machining project. Our CNC machining services come with tolerances as tight as 0.02 mm, and grinding tolerances can go as low as 0.001 mm. This precision ensures that each part meets your exact specifications, providing a perfect fit for your applications.

At Xuan Nan, we value our customers’ time. That's why we focus on fast delivery, completing most projects in just 3 to 7 days, depending on the order quantity. This quick turnaround time helps our clients meet tight deadlines and keep their production schedules on track.

We work with a broad range of materials, both metals and plastics, to cater to the diverse needs of our customers. Some of the materials we commonly work with include:

| Material Type | Common Grades/Types | Applications |

|---|---|---|

| Stainless Steel | 303, 304, 316, 420 | Corrosion-resistant parts, medical equipment |

| Carbon Steel | 1018, 1045, 1144 | Structural parts, automotive components |

| Aluminum | 6061-T6, 7075 | Lightweight, high-strength parts |

| Brass & Copper | C3602, H62 | Electrical components, connectors |

| Plastics | POM, ABS, Nylon | Insulated parts, non-metal components |

These materials allow us to meet a wide range of needs, from highly durable mechanical parts to lightweight plastic components.

In addition to machining, Xuan Nan also offers secondary processes such as welding, polishing, and finishing to ensure that your parts meet both functional and aesthetic requirements. Whether you need smooth finishes, coating, or custom welding for assemblies, we can handle it all.

Quality is a cornerstone of our CNC machining services. We have a rigorous quality control system in place to ensure that every part is made to the highest standards. From the initial design phase through to final production, every aspect of your project is thoroughly reviewed and inspected. Our quality assurance process includes:

Design for Manufacturing (DFM): We review your designs to ensure they are optimized for the CNC machining process.

Production for Manufacturing (PFM): We carry out a technical review to ensure that the final production process meets your specifications.

Material Inspection: All incoming raw materials are thoroughly inspected before machining.

In-Process Inspections: We perform quality checks during the manufacturing process to catch any issues early.

Final Inspection and Certification: We provide testing reports and certifications as per customer requirements before shipment.

Our commitment to quality ensures that you receive the best possible parts for your project.

At Xuan Nan, we take pride in offering not just machining services but also comprehensive project management and development. Here’s what you can expect when you work with us:

With over 10 years of experience, our CNC specialists have the expertise to guide your project from start to finish. We offer detailed project management services, ensuring that everything from the initial design to final production is effectively controlled. Our project management services include:

DFMA (Design for Manufacturing Analysis): We provide valuable insights into how the design can be improved for manufacturability, reducing costs and lead times.

PFMA (Production for Manufacturing Analysis): We analyze the entire production process to optimize efficiency and quality.

Our engineers and quality team work closely to ensure your projects are delivered on time and to the highest standards.

Xuan Nan is committed to providing fast and efficient delivery of your CNC machining projects. With our advanced machinery and streamlined production processes, we ensure that your parts are completed in a timely manner. For most projects, we can provide a quick turnaround of 3 to 7 days based on the order quantity.

We understand that different projects require different types of machining. That's why we offer a variety of services, including:

CNC Milling: Precision milling for complex geometries and high-precision parts.

CNC Turning: Perfect for cylindrical parts and shafts.

EDM (Electrical Discharge Machining): Ideal for intricate cuts and parts requiring high precision.

Secondary Machining: Services such as polishing, welding, and finishing to give your parts the final touch.

Our CNC machining services are highly customizable to meet the specific needs of your project. Whether you're looking for low-volume prototyping or high-volume production, Xuan Nan has the capacity and expertise to deliver the perfect parts for your needs. We work with you to understand your requirements and provide tailored manufacturing solutions.

At Xuan Nan, we are dedicated to providing our clients with the highest level of service, quality, and efficiency. Here’s why we are the best choice for your CNC machining needs:

Expertise: Our team of CNC specialists has over 10 years of experience in machining and project management.

Precision: We offer tight tolerances, with grinding tolerances as low as 0.001 mm, ensuring your parts meet exact specifications.

Fast Delivery: We understand the importance of time, and we offer fast delivery in just 3 to 7 days based on order quantities.

Wide Material Selection: We work with a variety of materials, including stainless steel, carbon steel, aluminum, brass, copper, and plastics.

Comprehensive Services: From prototyping to full production, we offer a complete range of CNC machining services, including post-processing and quality control.

If you're looking for reliable and high-quality CNC machining services, Xuan Nan is your trusted partner. Explore our CNC machining services and learn more about how we can support your production needs. Additionally, check out our Pressure Die Casting Services to complement your machining projects.

CNC machining is an essential part of modern manufacturing, offering precision, efficiency, and versatility. At Xuan Nan, we are committed to providing the best CNC machining services, delivering high-quality, customized parts that meet your specific requirements. Whether you're working on a small prototype or a large-scale production run, our expert team and state-of-the-art machinery ensure that your project will be completed on time, within budget, and to the highest standards.

Contact us today to get started on your CNC machining project and experience the Xuan Nan difference.