Views: 4 Author: Site Editor Publish Time: 2025-04-09 Origin: Site

CNC machining plays a crucial role in driving innovation. From aerospace to automotive, medical to electronics, CNC machining provides the precision and versatility needed to meet the diverse demands of various industries. At Xuan Nan, we specialize in offering cutting-edge CNC machining services that cater to the specific needs of multiple sectors. In this blog, we will explore the wide range of CNC machining applications across industries, highlighting how this technology is transforming manufacturing processes and helping businesses meet their production goals.

CNC (Computer Numerical Control) machining refers to the use of computer-controlled machines to perform operations such as cutting, milling, turning, and drilling to shape materials into precise parts. Unlike traditional manual machining, CNC machining automates the entire process, ensuring a higher level of accuracy, consistency, and speed. CNC machines operate based on pre-programmed software, allowing manufacturers to produce parts with extremely tight tolerances and complex geometries that would be difficult or impossible to achieve manually.

At Xuan Nan, we specialize in a range of CNC machining services, including CNC milling, turning, and cutting, providing custom manufacturing solutions for various industries. Our CNC machining process ensures that every part is crafted with the utmost precision, meeting your specific requirements.

CNC machining has revolutionized the manufacturing world by enabling high-precision parts to be produced quickly and cost-effectively. Some of the key benefits of CNC machining include:

Precision and Accuracy: CNC machines offer tight tolerances, ensuring that parts meet exact specifications.

Efficiency: Automated CNC machines can run continuously, reducing production time and labor costs.

Complexity: CNC machines can create intricate designs and geometries that would be difficult or impossible with traditional methods.

Customization: CNC machining provides the flexibility to create custom parts for specific applications.

Scalability: CNC machining can easily be scaled to produce both small batches and large volumes of parts.

With these advantages, CNC machining is used across a wide range of industries, each benefiting from the precision and versatility of this technology.

The aerospace industry is one of the most demanding sectors when it comes to manufacturing precision parts. Components used in aircraft and spacecraft must meet stringent safety and performance standards. CNC machining provides the level of precision required to produce these critical parts, including engine components, structural elements, and complex assemblies.

Applications in Aerospace:

Engine Components: CNC machining is used to produce turbine blades, engine housings, and other critical components.

Structural Parts: CNC machines are used to create lightweight yet strong parts for the fuselage and wings.

Custom Assemblies: From brackets to specialized connectors, CNC machining enables the production of custom parts for aircraft assemblies.

With Xuan Nan’s expertise in CNC machining, we help aerospace manufacturers create parts that meet the highest industry standards, ensuring both performance and safety.

The automotive industry relies heavily on CNC machining for the production of high-precision parts that contribute to vehicle performance, safety, and reliability. CNC machining allows for the efficient production of engine components, transmission parts, chassis elements, and more.

Applications in Automotive:

Engine Parts: CNC machining is used to create components such as cylinder heads, pistons, and engine blocks with tight tolerances.

Transmission Parts: Precision-machined gears, shafts, and housings ensure smooth and efficient power transmission.

Chassis and Body Parts: CNC machining helps produce structural components, brackets, and housings that are lightweight and durable.

Xuan Nan offers comprehensive CNC machining services to meet the exact specifications of the automotive industry, ensuring that parts are produced with precision and reliability.

In the medical field, the need for precision is even more critical, as components must meet high standards for safety and functionality. CNC machining is used to produce a wide range of medical devices and equipment, including surgical instruments, implants, and diagnostic tools.

Applications in Medical:

Surgical Instruments: CNC machines are used to create tools that require high precision and sharpness.

Medical Implants: Custom implants, such as hip and knee replacements, are made using CNC machining to ensure a perfect fit and functionality.

Diagnostic Equipment: CNC machining is used to create components for medical devices, including housings, connectors, and assemblies.

Xuan Nan’s CNC machining services ensure that medical parts are crafted with the highest level of precision and reliability, contributing to better patient outcomes.

The electronics industry demands parts that are small, lightweight, and precise. CNC machining allows manufacturers to produce components such as connectors, housings, and heat sinks with high accuracy and fine detail.

Applications in Electronics:

Connectors: CNC machining is used to create precise electrical connectors that ensure secure and efficient transmission.

Housings: CNC machining helps produce protective housings for electronic devices, such as smartphones, computers, and communication equipment.

Heat Sinks: CNC machining is used to create custom-designed heat sinks for electronic components that need to dissipate heat efficiently.

At Xuan Nan, we provide CNC machining services that help electronics manufacturers produce parts that meet the high demands of the industry.

Industrial equipment often requires durable, high-performance parts that can withstand heavy usage and extreme conditions. CNC machining allows for the production of robust components for machines used in manufacturing, construction, and energy sectors.

Applications in Industrial Equipment:

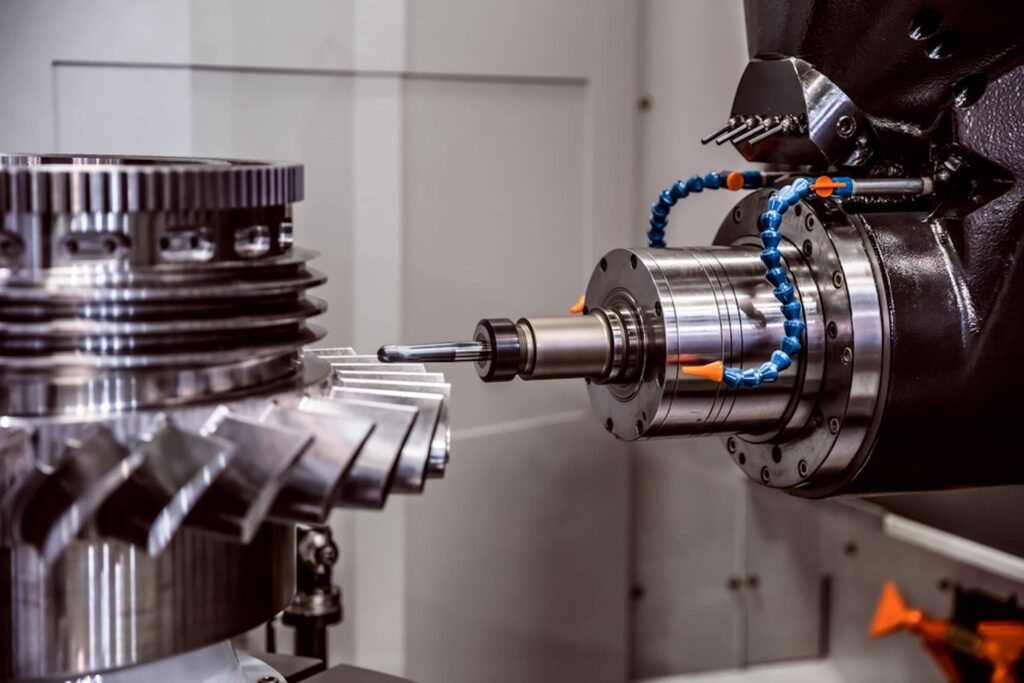

Machine Components: CNC machining is used to produce gears, pulleys, and shafts that drive machinery.

Construction Equipment: Components for cranes, excavators, and other heavy equipment are precision-machined to ensure durability and functionality.

Energy Systems: CNC machining is used to produce components for power generation systems, including turbines and pumps.

Xuan Nan’s CNC machining services help industrial equipment manufacturers create high-quality, durable parts that meet the demands of the industry.

CNC machining is also used in the production of consumer goods and jewelry. The ability to create custom parts with intricate designs makes CNC machining ideal for producing unique, high-quality products.

Applications in Consumer Goods and Jewelry:

Custom Jewelry: CNC machining is used to create detailed designs for rings, necklaces, and other jewelry pieces.

Consumer Electronics: CNC machining allows for the production of parts for consumer electronics such as tablets, cameras, and other devices.

Luxury Goods: High-end watches, pens, and other luxury items are often made using CNC machining to ensure precision and a premium finish.

CNC machining has been a driving force in innovation across many sectors. It has allowed manufacturers to explore new designs, produce parts with greater precision, and reduce the time required for prototyping and production. The ability to quickly create complex parts and test them in real-world conditions has accelerated product development and led to faster time-to-market for many industries.

Benefits of CNC Machining for Innovation:

Faster Prototyping: CNC machining allows for quick prototyping, enabling manufacturers to test and refine their designs before moving to mass production.

Customization: CNC machining provides the flexibility to produce custom parts that meet specific design requirements, opening up new possibilities for innovation.

Precision Engineering: The high precision offered by CNC machines allows for the production of complex geometries, enabling the development of new products and solutions.

Cost Efficiency: The efficiency of CNC machining reduces material waste and labor costs, making it an attractive option for innovative manufacturers looking to maximize their resources.

At Xuan Nan, we specialize in offering high-quality CNC machining services that help businesses across various industries innovate and thrive. Our state-of-the-art equipment and expert team ensure that every part is produced with precision, speed, and reliability.

Our CNC machining services include:

CNC Milling: Ideal for producing intricate parts and complex geometries.

CNC Turning: Perfect for manufacturing cylindrical parts with high precision.

Custom Manufacturing: Tailored CNC machining solutions to meet your unique requirements.

Explore our CNC machining services and learn how we can help bring your innovative ideas to life. Additionally, our Pressure Die Casting Services complement our CNC machining capabilities, providing complete manufacturing solutions for your projects.

CNC machining is revolutionizing industries by providing innovative solutions for manufacturing high-precision parts. From aerospace to automotive, medical to electronics, CNC machining plays a pivotal role in driving efficiency, innovation, and customization across various sectors. At Xuan Nan, we are proud to offer cutting-edge CNC machining services that help businesses stay ahead of the competition and bring their ideas to life.

Whether you need custom parts, rapid prototyping, or mass production, Xuan Nan is your trusted partner in CNC machining. Get in touch with us today to learn more about our CNC machining solutions and how we can help you innovate your industry.