Views: 3 Author: Site Editor Publish Time: 2025-04-09 Origin: Site

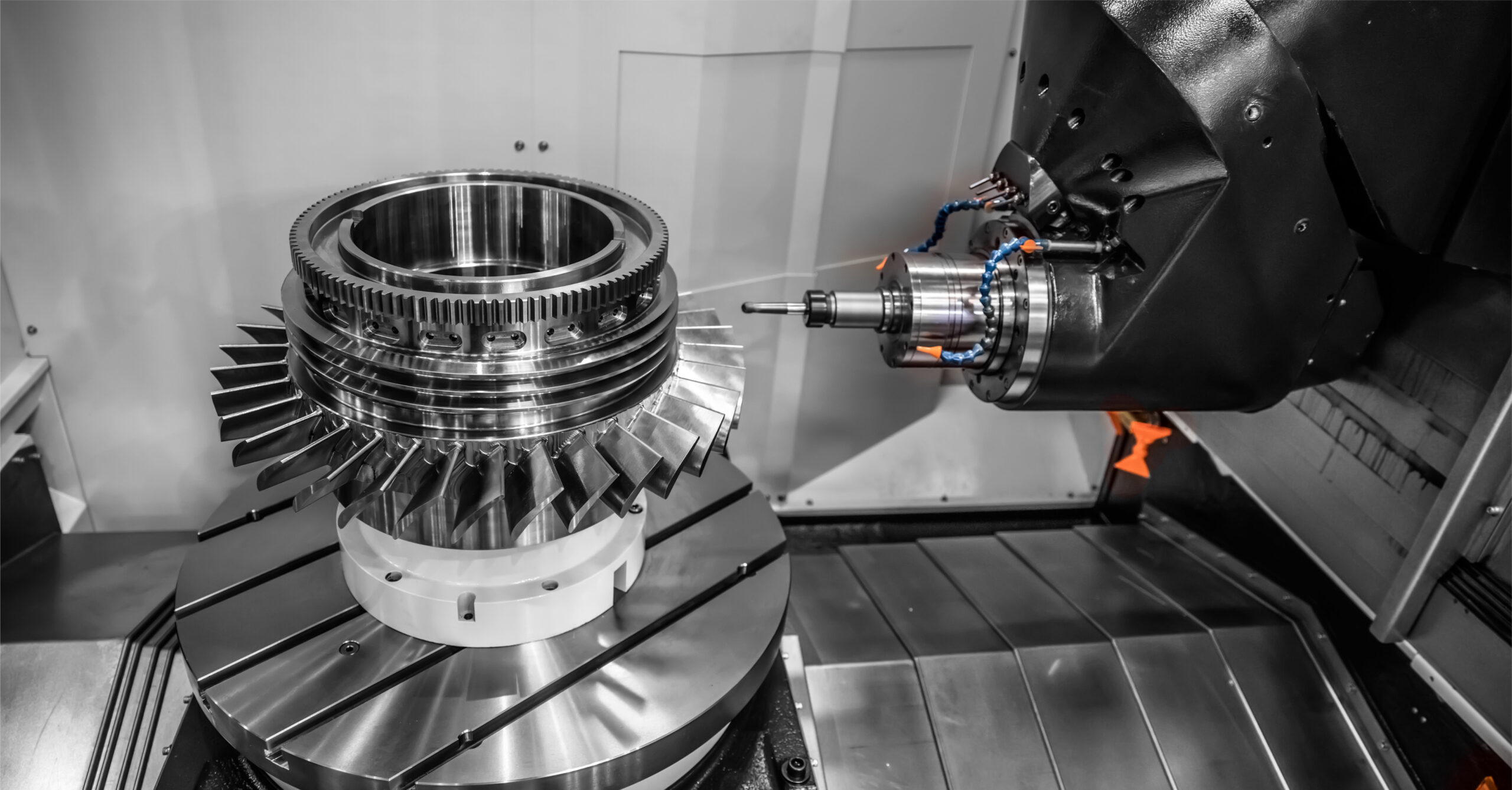

As we step into 2025, the demand for precision, speed, and cost-efficiency in manufacturing is higher than ever before. With rapid technological advancements, CNC machining has become the cornerstone of modern manufacturing, providing companies with the ability to create high-quality parts with intricate designs and tight tolerances. At Xuan Nan, we are proud to offer top-notch CNC machining services that cater to a wide range of industries, ensuring your projects are completed with precision, speed, and efficiency.

In this blog, we will explore the future of CNC machining services, why it's the best manufacturing option in 2025, and how Xuan Nan stands out as a trusted CNC machining company. We will dive deep into the various aspects of CNC machining, including the benefits, applications, and trends that are shaping the future of precision manufacturing.

Computer Numerical Control (CNC) machining is a manufacturing process where machines are controlled via computer software to carry out a range of tasks like cutting, drilling, milling, and grinding. CNC machining uses pre-programmed codes to dictate the movement of machines, ensuring high levels of accuracy, repeatability, and speed. Unlike traditional manual machining, CNC allows for greater consistency and the ability to manufacture complex geometries that would be difficult or impossible to produce using conventional methods.

In 2025, CNC machining continues to be the gold standard in manufacturing, and here’s why:

CNC machines can produce parts with tolerances as tight as 0.001 mm, making them ideal for industries that demand high precision. Whether you're in aerospace, medical devices, automotive, or electronics, the quality of your components can make or break your product. CNC machining ensures that every part meets exact specifications, reducing the risk of defects and ensuring reliable performance.

In today's competitive manufacturing landscape, time is money. CNC machining provides fast turnaround times while maintaining high precision. Advanced CNC machines can work continuously without interruption, speeding up production times and enabling manufacturers to meet tight deadlines. This efficiency makes CNC machining an excellent choice for both prototype development and large-scale production.

Although the initial setup cost for CNC machining can be higher than traditional methods, the long-term cost-effectiveness makes it a preferred option. The automation provided by CNC machines reduces labor costs, minimizes material waste, and maximizes the use of resources. For high-volume manufacturing, CNC machining ensures consistent quality and precision at a reduced cost.

CNC machining is highly versatile and can be used with a wide range of materials, including metals (stainless steel, aluminum, brass), plastics (ABS, nylon, POM), and composites. This versatility allows manufacturers to produce a wide variety of components for different industries, from simple brackets to highly complex aerospace parts.

At Xuan Nan, we offer a wide range of CNC machining services to meet the diverse needs of our clients. Whether you are looking for CNC machining parts, custom CNC machining, or high-volume production runs, we have the capabilities to deliver high-quality results. Our services include:

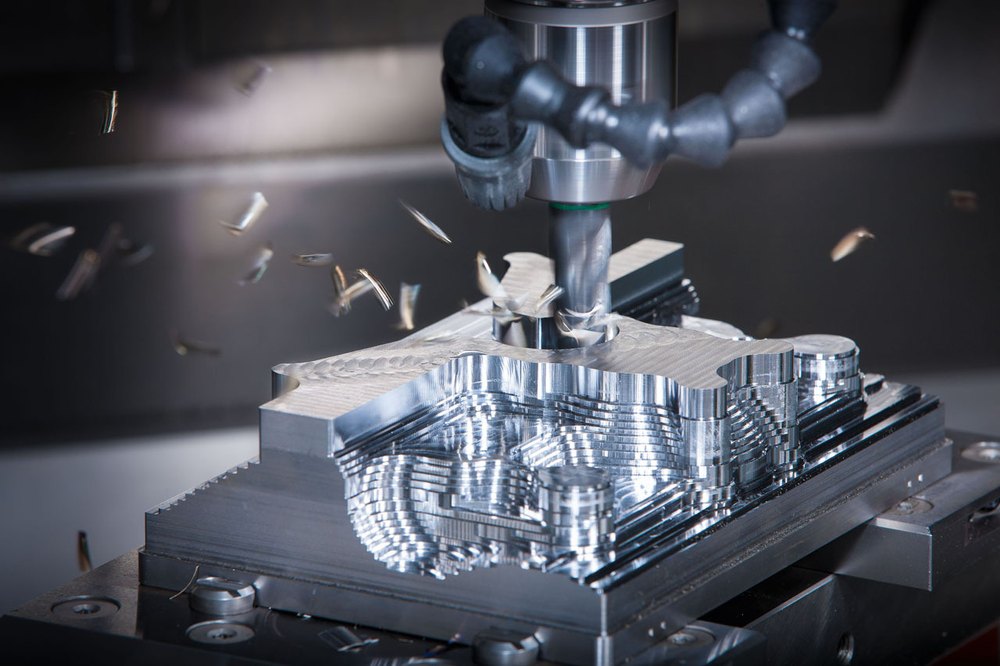

CNC milling is one of the most commonly used machining processes. It involves using rotary cutters to remove material from a workpiece, creating precise shapes and features. Xuan Nan’s CNC milling services are ideal for producing intricate parts with complex geometries and tight tolerances.

| Milling Type | Application | Benefits |

|---|---|---|

| 3-Axis Milling | Simple parts and features | Cost-effective, fast production |

| 4-Axis Milling | Parts requiring additional rotation | More complex features, greater flexibility |

| 5-Axis Milling | Complex parts with intricate geometries | High precision, reduced setup time |

CNC turning is perfect for creating cylindrical parts. The workpiece is rotated while a cutting tool shapes it into the desired design. CNC turning is ideal for parts like shafts, bushings, and fittings that require precise diameters and smooth finishes.

CNC grinding is used for parts that need a smooth finish or exacting tolerances that cannot be achieved with traditional milling or turning. CNC grinding is essential for parts requiring superior surface finish or tight tolerances.

For parts with intricate shapes or internal cavities, EDM is the preferred choice. This process uses electrical discharges to remove material, creating precise and complex shapes without the need for traditional cutting tools.

When you choose Xuan Nan for your CNC machining services, you gain access to a wide range of benefits that help streamline your manufacturing process:

At Xuan Nan, we specialize in providing custom CNC machining services. Whether you need a one-off prototype or a large batch of parts, our CNC machines can be programmed to meet your exact specifications. Custom CNC machining allows us to produce parts that are tailored to your needs, ensuring the highest quality and performance.

Our state-of-the-art CNC machines allow us to complete most projects in 3 to 7 days, depending on the order quantity. We understand the urgency of getting your products to market quickly, and our efficient production process ensures that your parts are delivered on time without compromising quality.

We maintain strict quality control throughout every step of the CNC machining process. From initial design to final production, our engineers and quality control team work together to ensure that every part meets your specifications. We also provide DFMA (Design for Manufacturing Analysis) and PFMA (Production for Manufacturing Analysis) reports for all of your projects to ensure manufacturability and cost-effectiveness.

Despite the high precision and advanced technology involved, CNC machining remains an affordable solution for manufacturing. At Xuan Nan, we work with you to ensure that your production runs are cost-effective, whether you're ordering a few parts or thousands. Our competitive pricing and efficient processes help reduce costs without sacrificing quality.

There are many CNC machining companies to choose from, but Xuan Nan stands out for several reasons:

With over 10 years of experience in the CNC machining industry, our team of experts is equipped to handle even the most complex projects. Our engineers and specialists are dedicated to ensuring that your project is completed on time, within budget, and to the highest quality standards.

We operate more than 25 sets of CNC milling machines, along with lathe machines, EDM machines, and laser cutting systems. Our advanced machinery ensures that we can handle a variety of machining operations, from simple to complex, with speed and accuracy.

Whether you need stainless steel, aluminum, brass, or plastic parts, we offer a broad range of materials for your CNC machining projects. We also work with specialty materials, ensuring that we can meet the specific needs of your project.

Xuan Nan provides CNC machining services not only to local businesses but also to clients across the globe. We offer online CNC machining services, making it easy for you to order parts from anywhere in the world. Our global reach allows us to work with a wide range of industries and deliver quality parts no matter where you're located.

If you're searching for "CNC machining services near me," look no further than Xuan Nan. With our online CNC machining services, we provide fast and reliable solutions to clients worldwide. Whether you're looking for custom CNC machining near me or need a trusted CNC machining company to handle your production, we are here to help.

If you’re ready to take your manufacturing project to the next level, explore our full range of CNC machining services at Xuan Nan. Whether you need CNC machining parts for prototypes or large-scale production runs, we are your one-stop solution. Don’t forget to check out our Pressure Die Casting Services for complementary services in your production process.

As we move into 2025, CNC machining continues to evolve with advancements in technology, automation, and materials. With its unmatched precision, efficiency, and versatility, CNC machining will remain a key player in the manufacturing world for years to come. At Xuan Nan, we are committed to providing the best CNC machining services, ensuring that your projects are completed on time, within budget, and to the highest standards.

If you're looking for reliable CNC machining services, whether online or near you, contact us today to discuss your project and see how we can help bring your ideas to life.